We prioritize quality and innovation in every step of the pome fruit processing. ensuring the preservation of their natural properties. With a focus on apples, pears, quince and other fruits we ensure the preservation of their natural properties. Our processing technology guarantees safe, stable, and enticing pome fruit juices and purées.

For the preparation phase, our machinery ensures the fruits are adequately prepared for juice extraction. The Bin Tipper UNLOADER 800 efficiently unloads fruits from pallet boxes, while the Sorting Conveyor meticulously sorts and dries the products, ensuring only the finest fruits proceed further.

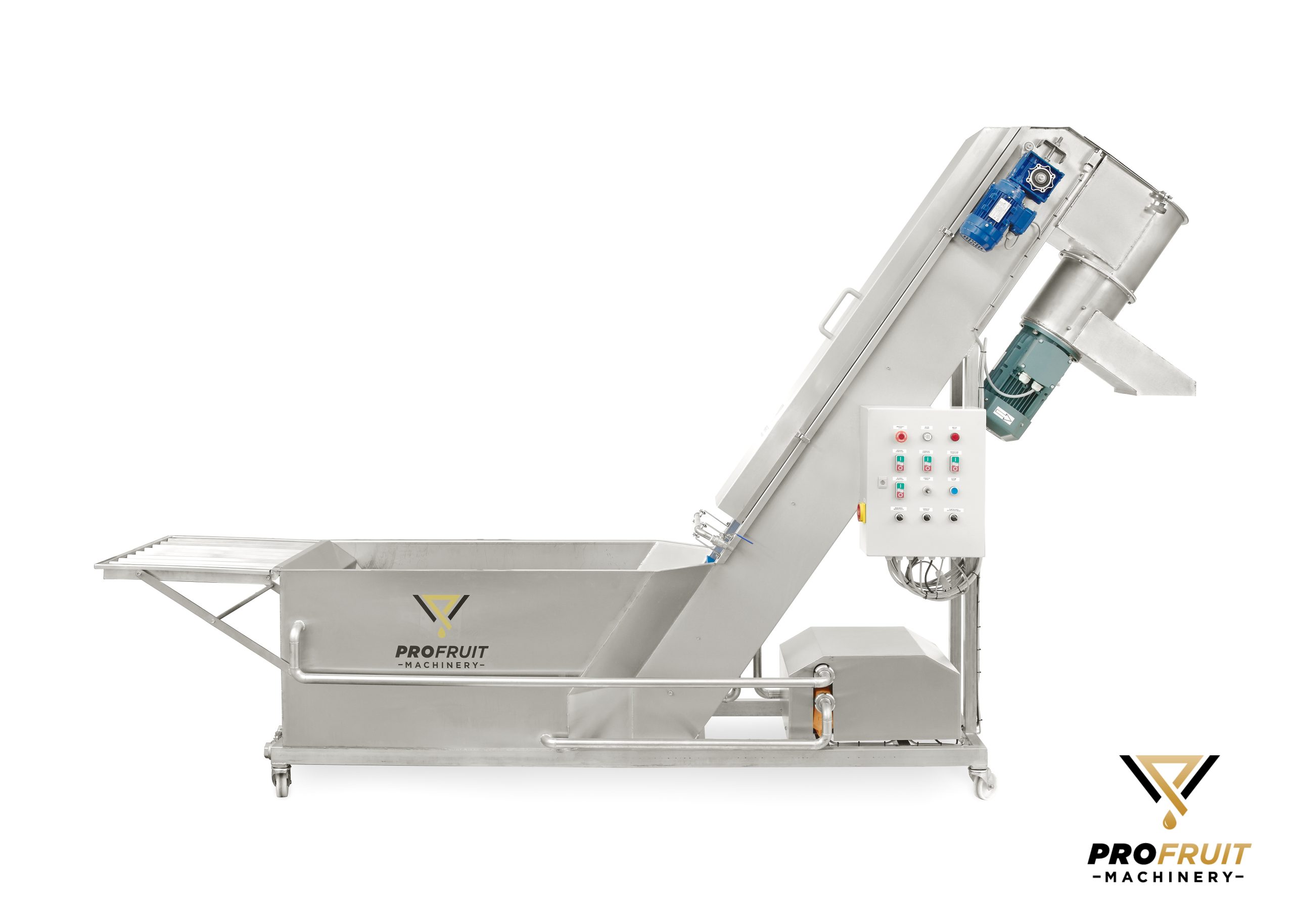

Next, the Fruit and Vegetable Washer AQUA 3000 gently washes and cleans the fruits, maintaining their integrity. The Fruit Bubble Washer Elevator Mill AQUAMILL or the Fruit and Vegetable Washer Elevator Mill MAXIMILL 1000-3000 then performs bubble washing and milling, transforming the fruits into a mash ready for pressing.

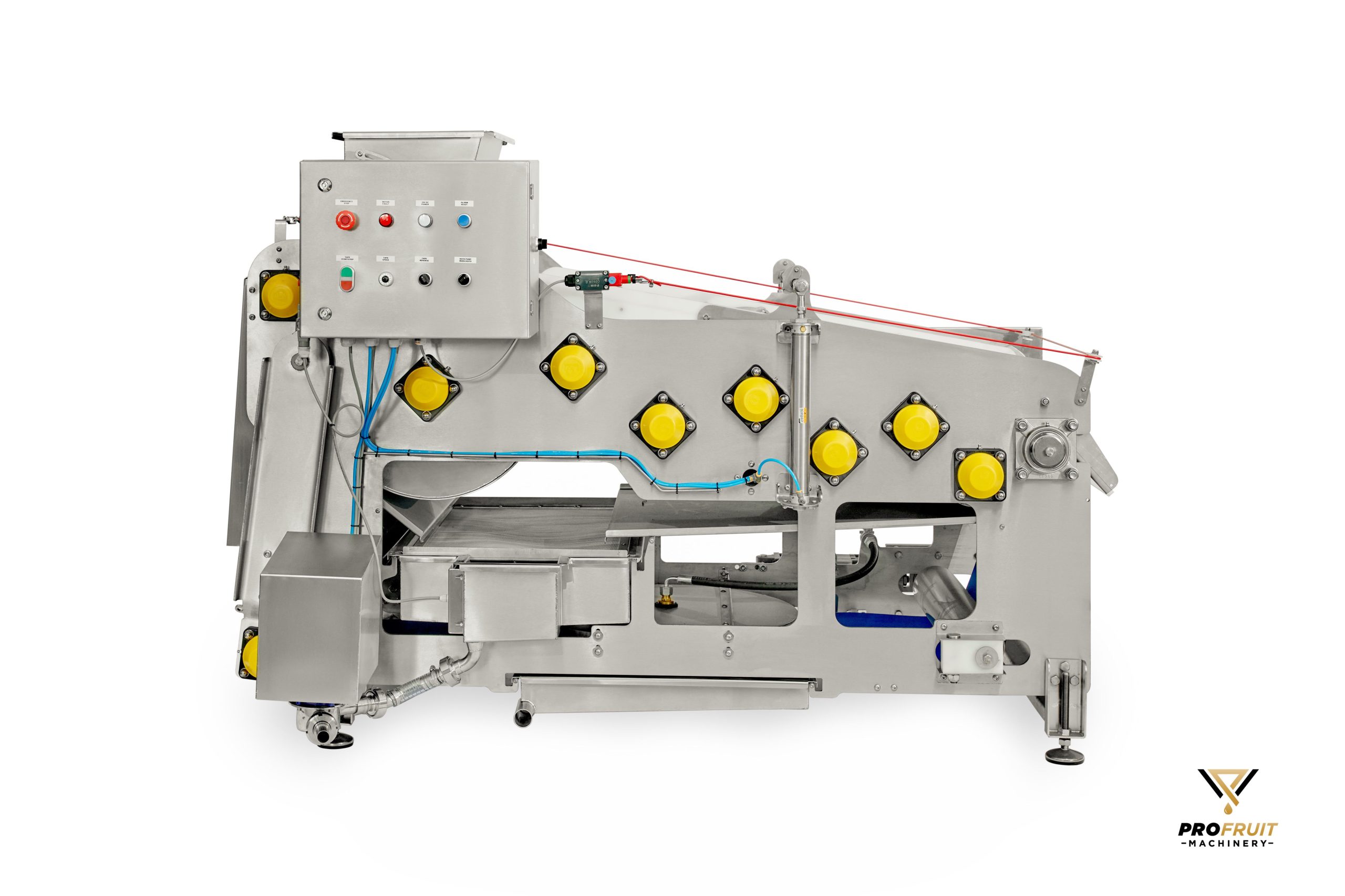

Our Belt presses POWERPRESS 400-800-1200-1500-3000 excels in pressing the fruit mass, extracting juice effectively. Leftover mash is seamlessly transported using the Screw Conveyor for Pressed Mash, minimizing waste.

To ensure uniformity and quality, the Juice Homogenizer reduces substances in the juice to tiny particles, distributing them evenly throughout the fluid. Subsequently, the electric Pasteurizer ECO HEAT or Diesel/Gas Pasteurizers pasteurize the juice, guaranteeing safety and extending shelf life.

Finally, our Automatic Bag in Box FIller AUTOFLOW efficiently fills liquids into Bag in Box and Stand up Pouch packaging, while the Manual Bottle Filler GRAVITY offers bottle filling options.

This pome fruit processing machinery line ensures superior outcomes, enabling businesses to provide top-notch fruit juices and purées.