In the intricate journey of puree and pulp production from fruits and berries, ProFruit Machinery manufacture innovative and modern equipment.

The process begins with the unloading of fresh produce through the precision of the Bin Tipper UNLOADER 800, swiftly transitioning into the sorting process facilitated by our advanced Sorting Conveyor.

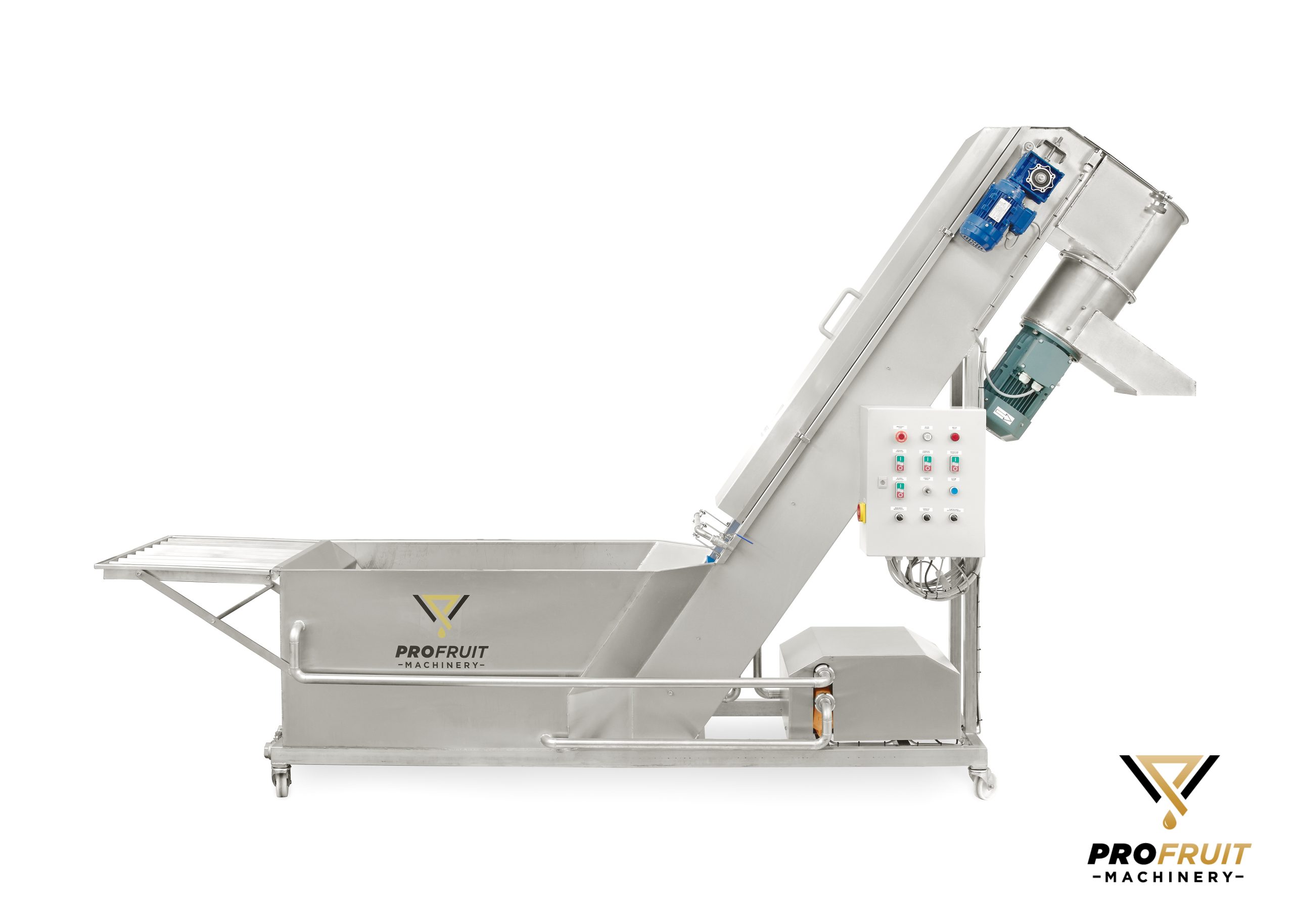

Once sorted, the product is washed and crushed using Fruit Bubble Washer Elevator Mill AQUAMILL. If berries comes prewashed, the process could be done with the Berry and Fruit Crusher.

Fruit & Berry mash is transferred by Monopump for Fruit Mash, to Tube in Tube Heat Exchanger, which ensures product ideal pressing temperature.

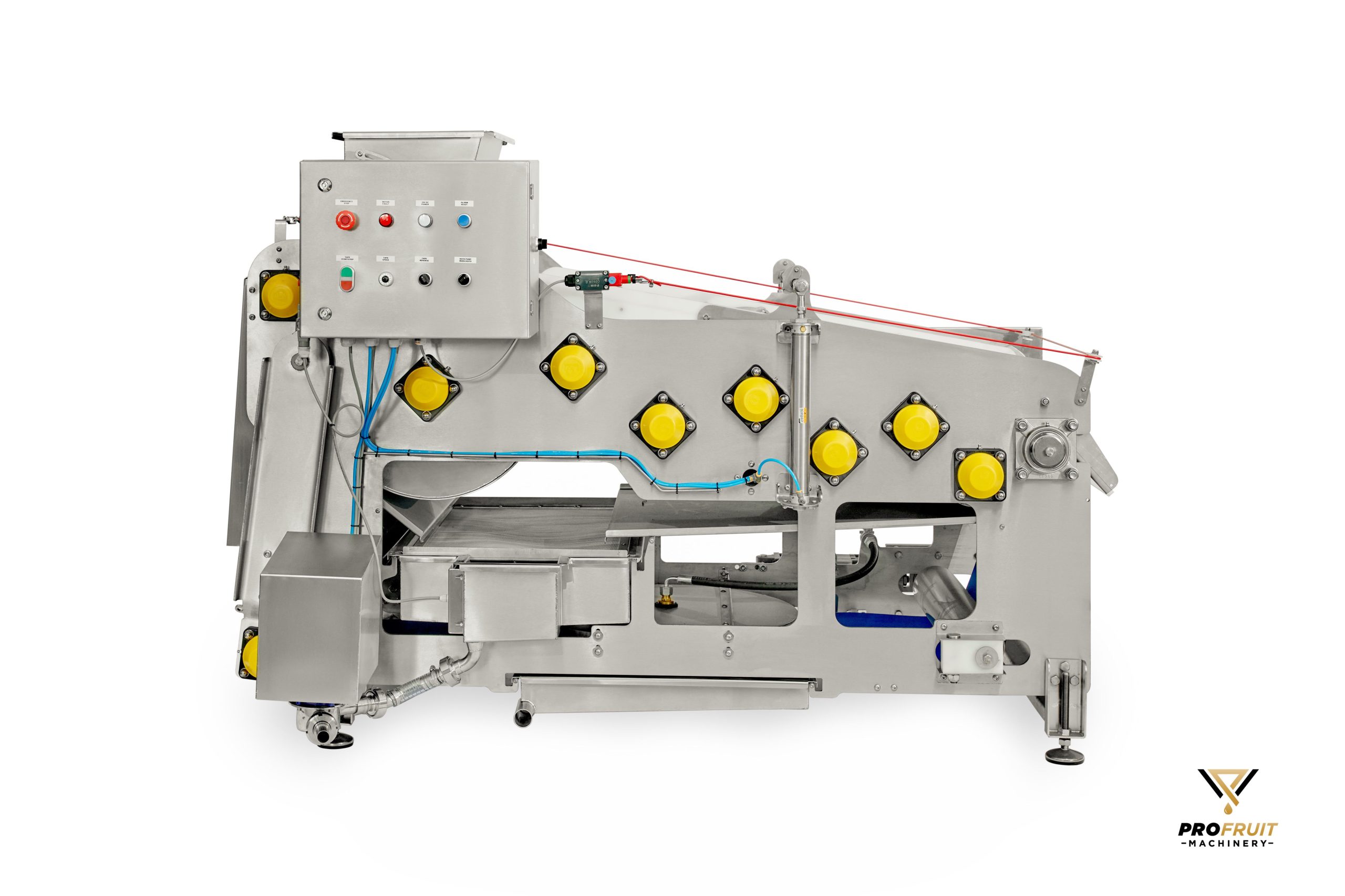

For smaller berries & fruits, the Destoning & Pulping Machine DESTONE 500-1000-2000 1st stage removes any unwanted elements, while larger stone fruits undergo the transformative process of the destoning 2nd stage, ensuring the extraction of puree and pulp.

You can ferment mash in our Stainless Steel Tanks for distillate production or if you are producing the pulp nectar then our Stainless steel closed tank with mixer is the best option of storing and mixing the juice. With the assistance of the Juice Homogenizer, consistency in product quality is ensured, meeting the highest standards of taste and texture.

In the final stages of juice processing, the juice undergoes pasteurization to ensure safety and prolong its shelf life. Businesses have the option to choose between the Diesel/Gas Pasteurizer HEAT 500/1000 or the Electric Pasteurizer ECO HEAT 300/500, each offering reliable pasteurization capabilities.

Finally, with our Automatic Bag in Box and Stand up Pouch filler AUTOFLOW or the Bottle filling and capping station-monoblock, businesses can effortlessly package their stone fruit juice, ensuring they are well-prepared for distribution and consumption.