ProFruit Machinery creates reliable machines for your cold juice processing needs.

The process using our equipment begins with the Bin Tipper UNLOADER 800, efficiently handling the intake of vegetables or fruits into the processing line. Next step includes the Sorting Conveyor, where operator sorts your products, guaranteeing only the finest produce moves forward.

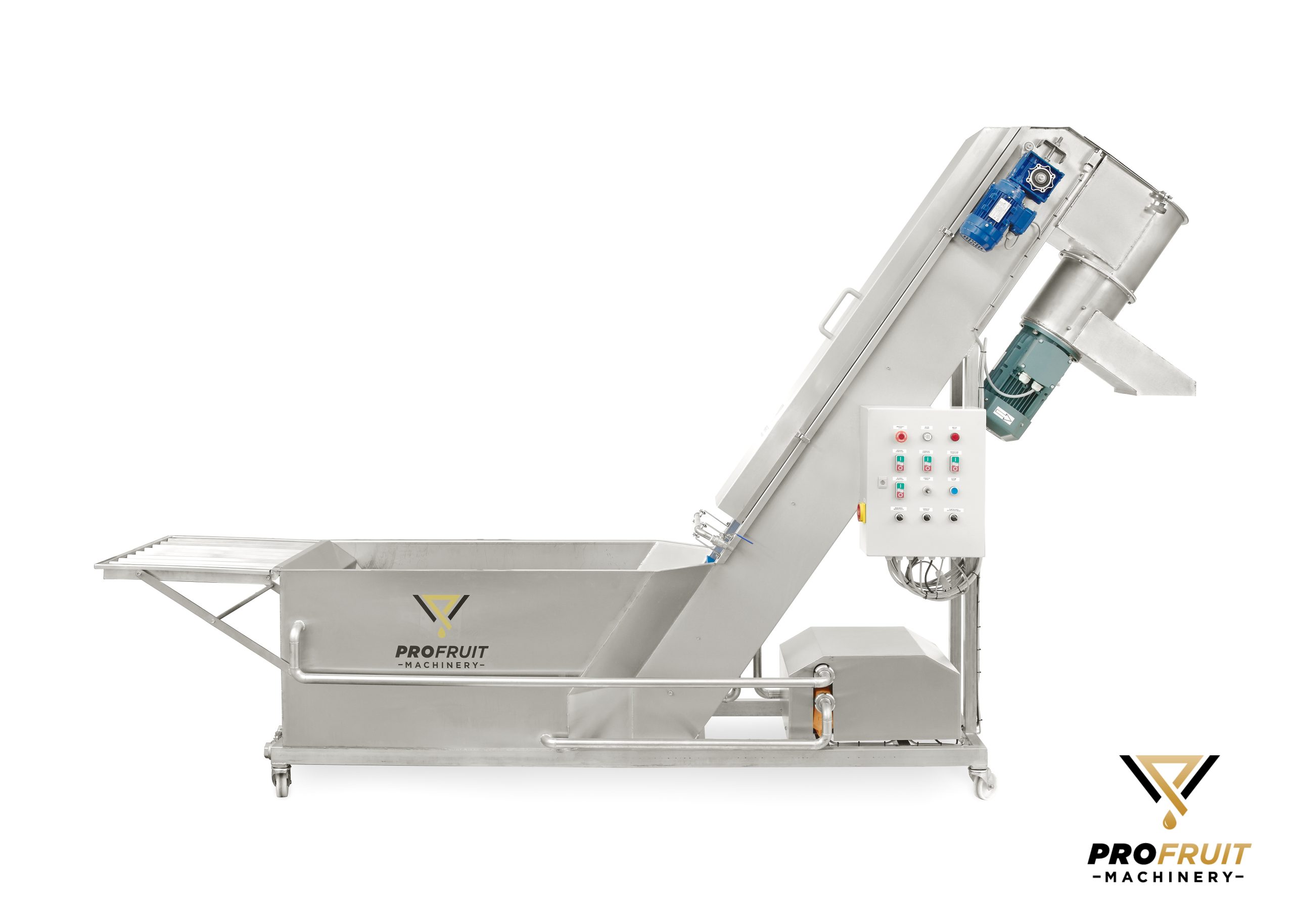

Peeled or polished vegetables like carrots or beets go into the Bubble Washer Elevator Mill AQUAMILL for finishing the washing process and milling the vegetables or fruits into a mash for further processing.

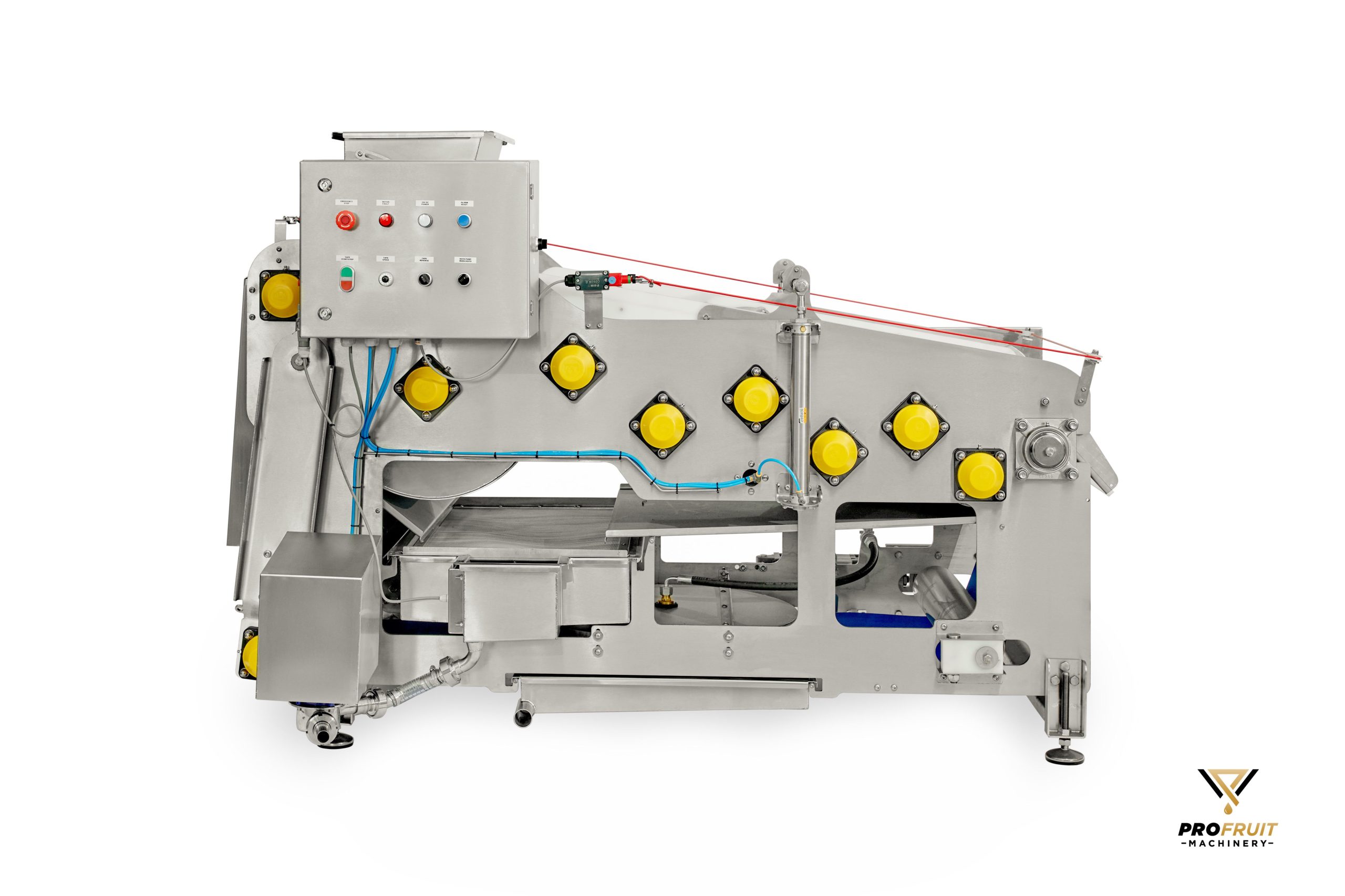

Juice extraction is facilitated by our POWERPRESS Belt Presses 400-800-1200-1500-3000. We focus on easy and efficient juice extraction while maintaining quality.

Efficient waste management is ensured through the Screw Conveyor for Pressed Mash, seamlessly transporting mash, minimizing waste and maximizing efficiency throughout the processing line.

The processed juice are transferred to our specialized Stainless Steel Tanks, designed for efficient collection.

Finished juice production can be directly filled to bottles with our Manual Bottle Filler GRAVITY. Also we offer theAutomatic Bag in Box Filler AUTOFLOW.

With ProFruit Machinery’s expertise in cold juice processing machinery, businesses can produce top-quality cold pressed juice production.