The efficiency is enormous. In one day now we press almost 3000 liters with one person. Last year, with two persons we pressed 1000 liters per day. So we are much more efficient.

ELEGAST CIDERY – The Netherlands

Arjen Meeuwsen

Owner of Elegast Cidery

The Netherlands

The Benefits

Our full 1200 kg/h fruit processing line increased efficiency significantly. It went from 1000 L per day (working with 2 persons), to 3000 L per day (working with 1 person).

Our machines managed to improve overall juice production performance. Besides bigger efficiency, one of the main benefits of purchasing a full line is assurance that all the machines work in perfect synergy. This led to a more convenient work process and easier maintenance – at Elegast cidery our machines require 50 % less of manpower.

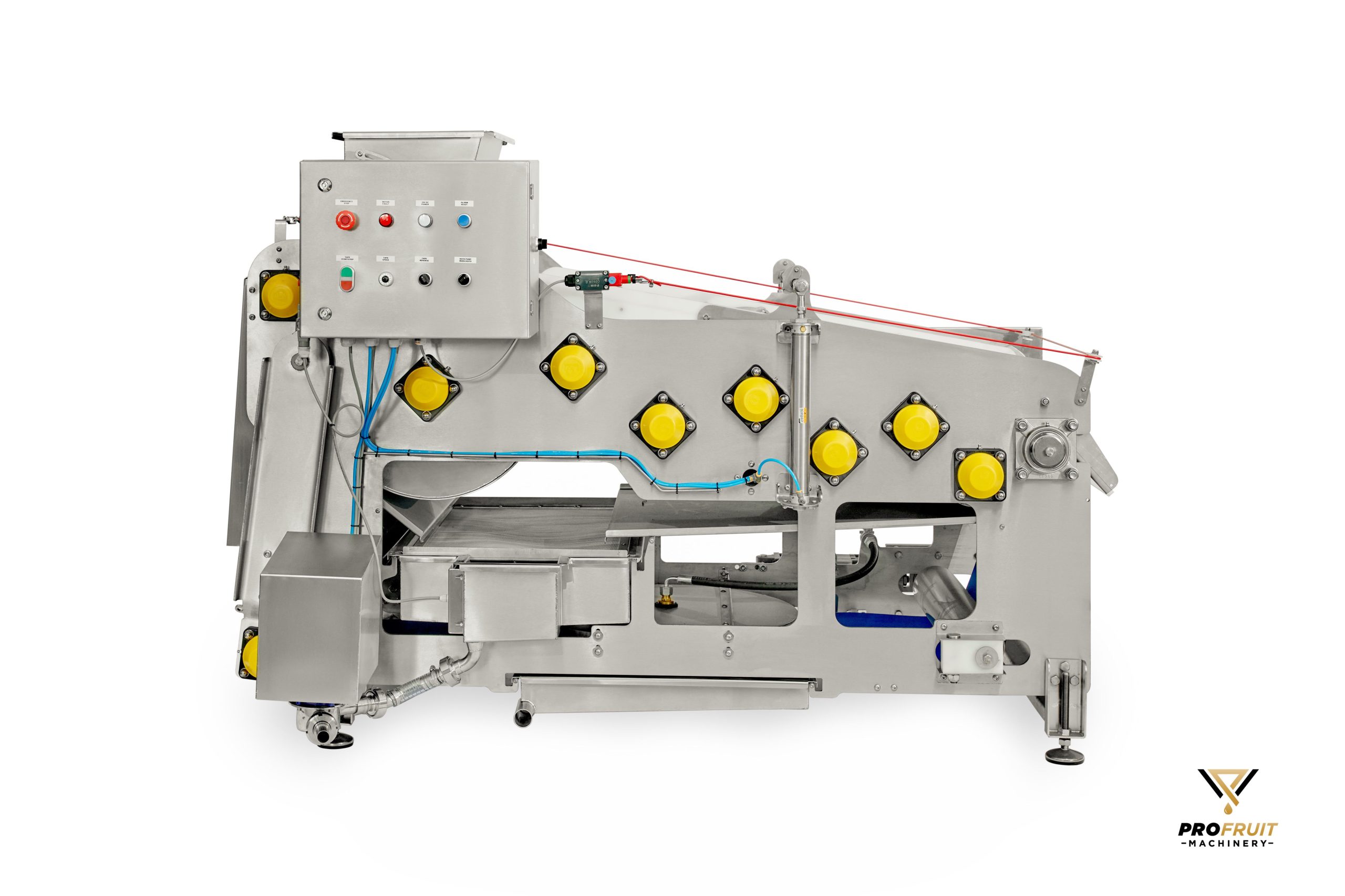

During the work process, bin tipper lifts up the box with apples and pours them onto conveyor. Conveyor transports products to the fruit washer elevator mill, which washes the apples and crushes them into a mash. Then mash enters the belt press – machine’s belt continuously presses mash against the cylinders and produce juice. Juice is filtrated by double juice filters and screw conveyor takes care of leftover mash by transporting it to outside container. After this, everything is prepared for fermentation process which leads to natural and delicious cider.

Increased efficiency

Less manpower required

The Client Bought

You can check out the machinery which our client ordered and inspect the details by clicking on any of the products below.

Sorting Conveyor

Fruit and Vegetable Washer Elevator Mill MAXIMILL 3000

Belt Press POWERPRESS 1200

Double Juice Filters

Screw Conveyor for Pressed Mash

Other Projects

Read the case study articles about our other projects where we customized our fruit processing and filling machinery and provided it to our clients from all over the world.